The top 10 IoT Use Cases

In short

- Adoption of various Internet of Things use cases is on the rise, according to the latest 2021 IoT Use Case Adoption report.

- Of the 200+ companies from various industries interviewed, the average company has adopted eight different IoT use cases to date out of a total of 48.

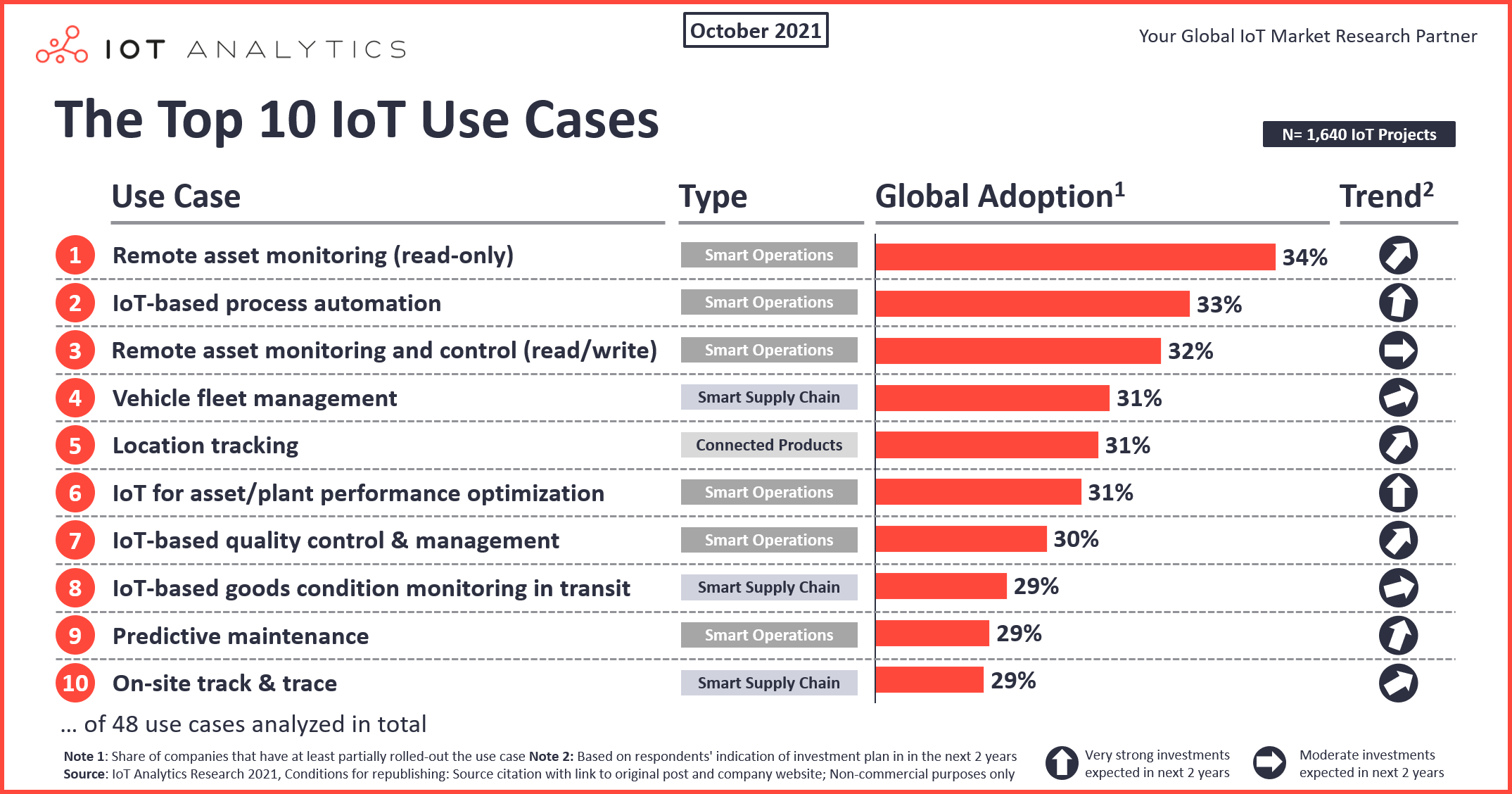

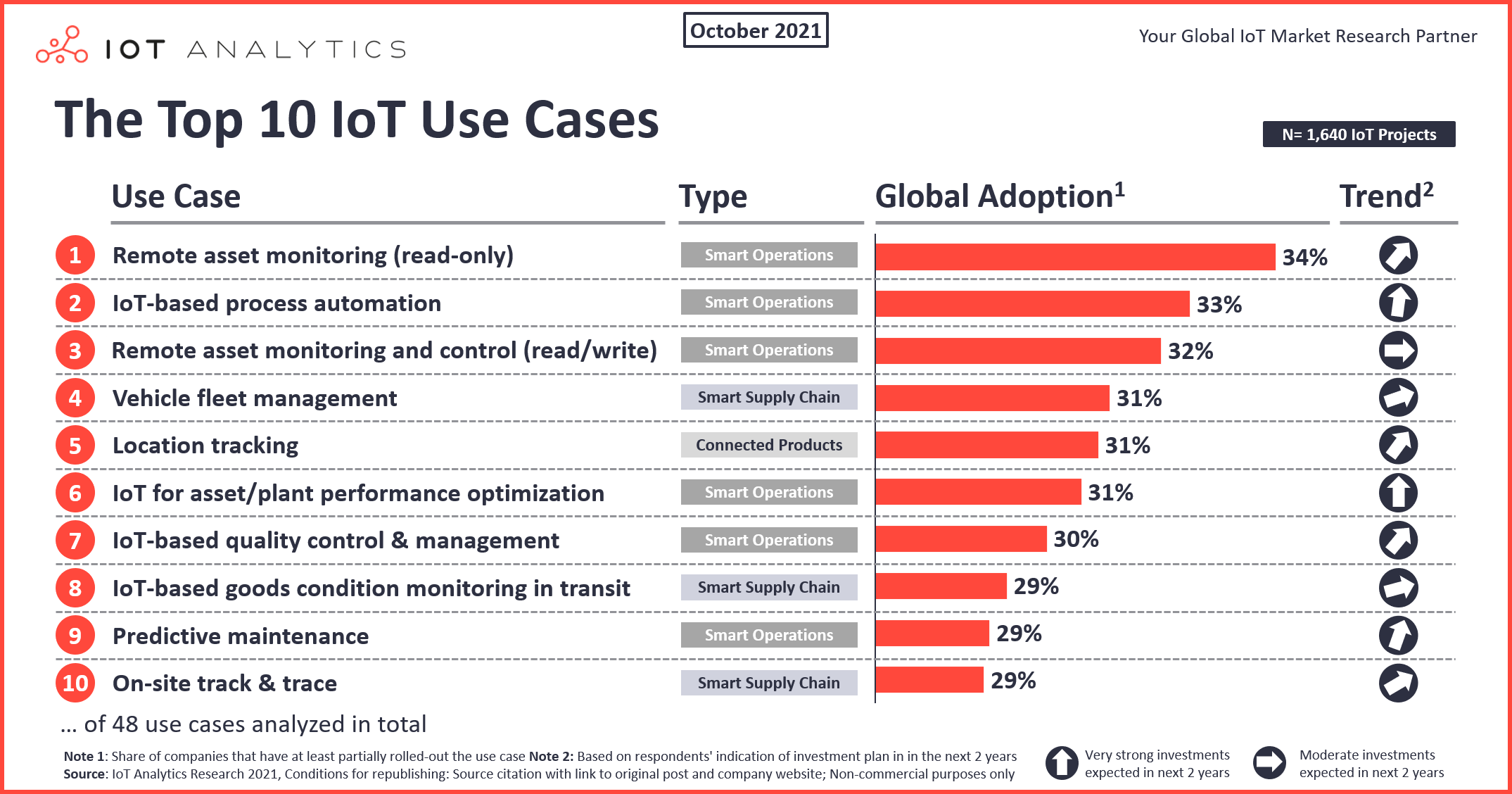

- IoT use cases related to the smart operations of a company are the most adopted, followed by smart supply chain use cases and use cases involving connected IoT products.

- Read-only remote asset monitoring is the most widely adopted use case 34% of companies interviewed have adopted it.

Why it matters?

- With various IoT topics prioritized by organizations post-COVID, getting a feel for what is hot and what is not is important for both vendors and IoT adopters.

- Vendors should prioritize those use cases that yield a high return on investment (ROI) and those that are on the investment priority list in the coming years.

- IoT adopters can learn from the best practices and examples of existing users to prevent costly mistakes.

The IoT Use Case Adoption Report 2021

In 2021, the average large manufacturing, healthcare, automotive, retail, or energy company has rolled out eight different IoT use cases, according to IoT Analytics’ latest IoT Use Case Adoption Report.

The 430-page report, which is part of IoT Analytics’ ongoing market coverage of IoT applications, is the first such in-depth report and is based on 200+ interviews with IoT end users who have rolled out more than 1,600 IoT projects over the last few years across 48 different IoT use cases. The report shows where companies have been investing and are planning to invest, which industries and regions are ahead, and which use cases promise the highest ROI.

Oil and gas companies and energy companies are ahead of others. They have rolled out an average of 15 use cases. Make no mistake: For many companies, IoT is still a small fraction of their business. The average company we interviewed had $9.6 billion in revenue and only currently spends $33 million on IoT use cases (0.34% of the revenue). The fact that the top use case today has only been adopted by 34% of respondents (but with a predominantly positive ROI) shows how much bigger the IoT opportunity is.

Note: The report looks at IoT use cases that are applicable to most organizations and does not consider industry-specific use cases such as smart heating, ventilation, and air conditioning (HVAC) (applicable only to buildings) or smart transportation systems (applicable to cities). The analysis also does not consider consumer IoT use cases such as Smart Home devices or wearables. For a broader analysis of enterprise IoT applications, see this analysis from 2020. For a deep dive on Smart City IoT use cases, see this analysis. A deep dive on Smart Building use cases will be published later this year.

The 10 most adopted IoT Use Cases

Six of the top 10 IoT use cases today (ranked by adoption) aim at making operations smart, thus improving companies’ production processes for manufacturing, enhancing maintenance operations, or advancing any other operations (e.g., energy generation in the case of an energy company, running healthcare operations in the case of a hospital, or running store operations in the case of a retail company). Three of the top 10 use cases are related to smart supply chains, and only one is related to smart products in the field.

Here are the 10 most adopted use cases, ranked by their adoption rate:

1. Read-only Remote Asset Monitoring

Not surprisingly, the simplest IoT use case is also the most adopted. Read-only remote asset monitoring refers to assets that are connected from afar in a read-only manner (i.e., one can visualize the asset data, but one cannot send back any commands to the asset itself). This use case is one of the easiest and cheapest to set up due to its simplicity. In many cases, remote asset monitoring supersedes the error-prone and costly manual task of checking and documenting asset states in person. Adoption in 2020 was clearly accelerated by the pandemic and is expected to grow even further, as 36% of interviewees say they plan to invest significantly in this use case in the next two years.

Adopter’s quote

“In the future, our engineers and plant operations staff will not need to sit in cars to go from their office location to another sub-station or satellite equipment room to perform daily routine activities. Routine read-only activities could be done more frequently, which could indirectly contribute to the reliability of control systems.”

Senior operations manager of a mining company in Qatar

Implementation example

Hindustan Coca-Cola Beverages Pvt. Ltd., located near Pune, India, adopted remote asset monitoring for its PET and can-bottling lines. The real-time and continuous monitoring of critical parameters (e.g., syrup flow rate, can-rinse pressure, and water temperature) replaced its MS Excel-based manual reporting. In this specific case, the company combined the remote connectivity of its assets with a condition-monitoring use case that generates alarms based on predefined conditions.

| Use case definition (by IoT Analytics)

Remote Asset Monitoring (read-only) = Real-time, one-way data streaming from machinery/equipment to an offsite location (e.g., cloud), making data accessible from anywhere.

2. IoT-based Process Automation

IoT-based process automation has been rolled out by 33% of companies. This type of process automation describes operational processes that were either entirely manual in the past or relied on antiquated, industrial-automation setups but have now been upgraded with state-of-the-art hardware and software. Companies that introduce this use case to upgrade their existing setups often do so to add flexibility and agility in the operations process so that specific process steps can be changed in the future. This becomes important because companies are increasingly interested in aligning their manufacturing and operations processes to ever-changing customer demands.

Adopter’s quote

“Our manufacturing processes used to have many paper-based steps involved. IoT process automation has reduced many of these paper-based processes, resulting in a reduction in the number of errors, labour cost and real-time access to data.”

CIO of a food and beverage manufacturer in Canada

Implementation example

An Australian farmer, reported he was able to use 20% less water thanks to a new IoT-based irrigation system supplied by Lindsay, a US-based manufacturer of pivot-irrigation systems. Farmers increasingly adopt smart IoT-based irrigation systems to automate the process of irrigation and thereby enhance their crop yields.

| Use case definition (by IoT Analytics)

IoT-based Process Automation = The use of real-time data from connected assets to improve an entire operational process (e.g., a manufacturing process).

3. Remote Asset Monitoring and Control (read/write)

“Read/Write remote asset monitoring and control” is the extension of “Read-only remote asset monitoring.” On top of “reading” the assets data, with this setup one can also communicate back and thereby influence asset control from afar (i.e., “writing” data back).

Just like the read-only asset monitoring use case, this use case was accelerated by the COVID-19 pandemic as service teams, engineers, and other staff needed to find ways to reach an asset that needed their attention while being in a different location.

Because of the added complexity and security risk of controlling an asset, on top of just simply monitoring, this use case comes with significantly higher costs of installation and maintenance. However, it has been proven that such solutions pay off in a relatively short time: Of those decision makers whom IoT Analytics interviewed, 51% reported amortization in less than 24 months.

Adopter’s quote

“Remote monitoring and control of freezers has saved costly materials before being ruined.”

Research and development (R&D) manager of a manufacturing company in UK

Implementation example

Schlumberger, an oilfield service company, recently adopted a monitoring and control solution from Advantech and ReStream. These companies had partnered up to supply and develop a new oilfield fluid-monitoring system based on LTE connectivity. The project helped to achieve flow assurance, ensure asset integrity, and optimize production. It also helped to increase labor safety. Oilfield companies suffer from a dynamic chemical environment that, if unchecked, can lead to premature wear, lost productivity, and the release of lethal poisonous gases.

| Use case definition (by IoT Analytics)

Remote Asset Monitoring and Control (read/write) = Real-time, two-way data streaming of machinery/equipment from/to an offsite location, enabling data access and the sending of commands from anywhere.

4. Vehicle Fleet Management (track/trace)

The management of vehicles in a fleet is the number one IoT supply chain use case right now. The larger the fleet of trucks (or other means of transport) to manage, the higher the complexity. Cross-border fleet management can be especially overwhelming, which is why 31% of companies have rolled out a professional vehicle fleet management solution to gather real-time information.

Today, most fleet management solutions are reliant on wide-area connectivity, such as cellular (2G, 3G, 4G). Several new, low-cost IoT satellite technologies have recently been launched and promise to add another option to this use case so that vehicle fleets are always truly connected at a reasonable price. New companies include Hiber (IoT-focused satellite network) and Starlink (part of SpaceX). Both plan to send thousands of new satellites into space in the coming years to provide low-latency, high-bandwidth connectivity globally.

Adopter’s quote

“Now we know virtually in real time where our wagons are located, which routes we can optimize, and where there is potential for savings for our customers.”

Suzy Verachten, project leader, Lineas European Rail Freight Operator

Implementation example

Lineas, the largest private rail freight operator in Europe, managed to increase capacity utilization of its fleet by more than 40 percent by implementing the Bosch fleet management solution.

| Use case definition by IoT Analytics

Vehicle Fleet Management track/trace = Tracking and tracing the location of individual vehicles either on site while in transit or as general fleet management.

5. Location Tracking e.g., GPS

Not every company sells smart-connected IoT products, but of those that do, tracking the location of the asset is the number one use case 31% of companies in our interview set have adopted it. The results from this interview series are in line with results from the IoT Commercialization & Business Model Report 2020, which found that geolocalization was also the number one use case in terms of customer adoption when original equipment manufacturers OEMs were asked which smart product features their end customers were adopting as part of their IoT-enabled assets. Location tracking is therefore important for developing a successful IoT business model.

Tracking the location of an asset can be beneficial to both the vendor of the products e.g., by understanding usage patterns and to the user e.g., by finding a lost item or by mitigating theft.

Adopter’s quote

“Connectivity means we can monitor distance covered, send service alerts, or lock the bike remotely. Things become even more interesting when we mesh this data with other transport data. If we can map the routes of thousands of cyclists, could we help urban planners develop better cycling infrastructure?”

Taco Carlier, co-founder, VanMoof

Implementation example

VanMoof, an Amsterdam-based e-bike manufacturer, offers an anti-theft service to its customers that is based on the location tracking of a bike. For a monthly fee, the company sends its “bike hunters” if a customer’s bike is stolen. The bikes are connected and tracked by a combination of Bluetooth and cellular networks. This allows the company to keep its promise of recovering the bike in up to 70% of cases.

| Use case definition by IoT Analytics

Location Tracking e.g., GPS = Tracking product location to determine its movement and geographic position.

6. IoT for Asset/Plant Performance Optimization

Asset performance management APM is a term in manufacturing to describe methods of capturing and integrating data, visualizing it, and analyzing it to improve the reliability and availability of physical plant–floor assets. IoT for asset/plant performance optimization is the modern version of APM. It integrates state-of-the-art data-capture and integration tools like IoT gateways and software tools like IoT platforms to analyze how assets can be run and maintained at optimum levels e.g., optimized asset speed settings, optimized material input settings, or optimized maintenance intervals.

More than 30% of companies in our interview set have adopted IoT for asset/plant performance optimization. With 42% of companies planning to invest significantly in IoT for this purpose, it is among the use cases with the highest expected growth rate.

Adopter’s quote

“The use of IoT for plant performance optimization has been a success since it now allows us to run our CHP power utilities at optimal levels based on variable fuel mix and plant loads for steam and power.”

CEO, manufacturing: chemicals and chemical products, India

Implementation example

A beverage manufacturer that was running mostly older equipment used an IoT solution provided by Relayr in one of its bottling plants, which produces 1.2 million bottles per day per production line. It achieved improvements of 11% in performance and 8% in quality. Implementing an IoT retrofit kit and an IoT gateway, the company was able to identify the processes responsible for 90% of the plant’s downtime. Based on the IoT data collected from the legacy machinery of different manufacturers, the company was able to address several issues e.g., changing the control logic of the machines.

| Use case definition by IoT Analytics

IoT for Asset/Plant Performance Optimization = The use of real-time data from connected assets to optimize individual asset health for better operations performance at a site.

7. IoT- based Quality Control & Management

IoT-based quality control and management involves the use of machine vision or other IoT sensor data to detect quality issues in real time during operations. The use case pays off particularly quickly: Of the 30% of companies that have implemented this IoT use case, two-thirds report amortization in fewer than 24 months.

Adopter’s quote

“We can now tell quickly if the environmental parameters are not quite right at some point, either within the paint shop or in one of the buffer areas. It takes a lot of data to do this, which we collect throughout the process, evaluate historically and analyse in real time”

Martin Hilt, innovation and digitalization officer at BMW

Implementation example

A leading global automobile manufacturer automated the testing of the electronic functionality of its cars during the manufacturing process. As the company was adding greater electronic functionality to the cars to stay current with technological developments, it was looking to find ways to optimize its time-consuming, manual method of checking the operation of electronic parts. With the help of Cognizant, the company was able to completely automate vehicle testing and also implement a mixed-mode validation to simulate missing parts that would arrive late due to unforeseen supply chain issues. The solution realized a positive return on investment in four months.

| Use case definition by IoT Analytics

IoT- based Quality Control & Management = The use of IoT sensor data or machine vision to monitor operational process parameters and detect faults in real time with the goal of reducing scrap/rework.

8. IoT-based goods condition monitoring in transit

Monitoring the conditions of goods is essential in industries such as pharmaceuticals or food and beverage and can even be seen as a way to help tackle the global food shortage. Temperature sensor data is one of the most important sensor values for this use case; it guarantees the safety of the final product by close monitoring throughout the entire supply chain, both in transit and in storage.

Condition-monitoring solutions were used by 29% of the interviewed decision makers as part of their digital supply chain initiatives.

Adopter’s quote

“The assessment [of goods in transit] was an eye-opener, because we never looked at supply chain risk holistically before. Now we know where the risks are.”

An D’haenens, logistics manager EMEA, DuPont

Implementation example

A global life sciences company worked with DHL to enable pallets with smart sensors. The sensors are equipped with low-power wide-area LPWA connectivity and track geographic location, movement, delay, shock, and temperature. This ability has enabled the life science company to reduce its life-cycle costs by 6 to 7%, with reported reliability of nearly 100%.

| Use case definition by IoT Analytics

IoT-based goods condition monitoring in transit = The use of IoT sensor data to monitor the condition of transported goods and ensure they remain safe and are not exposed to the wrong temperatures or shocks.

9. Predictive Maintenance

To forecast the remaining useful life of assets and ensure they are repaired before they fail, 29% of all companies have invested in solutions at the intersection of artificial intelligence and maintenance. As IoT Analytics highlighted in a recent blog post, predictive maintenance PdM is an en vogue topic, with 40% of interviewed decision makers planning to invest significant amounts of money in the coming two years.

Adopter’s quote

“PdM enabled us to actively monitor highly critical assets, provided us with multiple feeds of various data points temp, vibration, throughput, allowed [us] to perform analysis of the asset health in real time, and helped us to prevent the need [for] reactive maintenance actions for critical assets.”

IT director at an Oil&Gas company in the United States

Implementation example

Colgate-Palmolive Company, a US-based consumer goods manufacturer, leveraged a predictive maintenance solution to optimize its manufacturing capacity and prevent costly downtime. It installed wireless sensors on 2,000 machines including tube makers and liquid machines to collect machine data. The predictive maintenance solution detected increased temperatures and alerted staff, thereby preventing nearly 200 hours of downtime and a missing output of 2.8 million tubes of toothpaste.

| Use case definition by IoT Analytics

Predictive Maintenance = The use of real-time IoT sensor data and artificial intelligence AI techniques to determine when maintenance should be performed on specific equipment.